Products

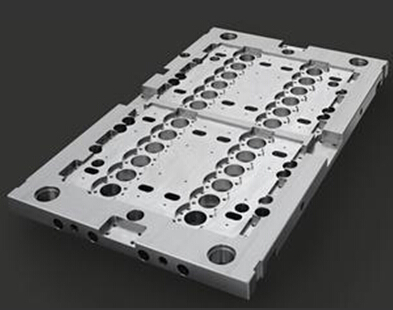

| Die cryogenic treatment | |

|

Definition: cryogenic environment mainly refers to the material handling needs -190 ° C to -230 ° C of. (Non-liquid nitrogen medium temperature refrigeration whole computer) OrderHotline:400-6388-689 |

|

Definition:cryogenic environment mainly refers to the material handling needs -190 ° C to -230 ° C of. (Non-liquid nitrogen medium temperature refrigeration whole computer)

Applicable materials: All metal or nonmetal materials, such as alloys, carbides, plastics (nylon and Teflon), aluminum and ceramics.

Cryogenic Technology: When the metal and hard to cool down in the heat treatment process, which produces alloy and carbon dissolution and diffusion combined with the formation of austenite (Austenite), during the cooling process, due to the low temperatures to produce suppress the formation of martensite ( Martensite), and because the final transition point martensite (Mf) is very low, for example,

Such as: W18Cr4V (high-speed tool steel) of more than Mf point -190 ° C, cooled to room temperature and quenched and therefore a lot of residual austenite will thus reduce the hardness of metals, wear resistance and service life, and because austenite high brittle fracture easily cause the metal, and further, there are many physical properties, especially thermal and magnetic properties decline.

Scientific:

1, due to the very strong and decomposition of austenite at low temperatures, so that the original defects (pores and the stress concentration part) and becomes plastic flow structure refinement, so long as the metal placed in cryogenic environments, wherein the austenite into martensite, thereby eliminating stress.

2, in the ultra-low temperature due to the contraction of the tissue volume, Fe lattice constant narrowing and precipitation of carbon atoms to strengthen the driving force, so the large amount of martensite in the matrix of ultrafine precipitated carbides, these ultra-fine crystals experience to improve the strength of materials, while increase the wear resistance and rigidity.

3, ultra-low temperature metal atom can be transferred transport capacity, so that can not be separated so that the atomic diffusion between atoms bonded more tightly.

Su's heat treatment Co. Ltd. was founded in 1990, after decades of development, scale is continually expanding, is located in Shajing Town Baoan District Shenzhen City Bridge second industrial zone, covering an area of 3000 square meters, the main business is to take all the metal, alloy steel, beryllium copper, heat treatment of high speed steel, cryogenic treatment (-196 C), nitrogen gas, liquid nitrogen, QPQ salt bath production line, high-frequency quenching, blackening and carburizing, the surface of hard and stainless steel processing.

The company is equipped with power of heat treatment technology, established a perfect quality testing equipment, equipped with vacuum quenching furnace, vacuum furnace, pit furnace, furnace, liquid nitrogen atmosphere furnace, rotary furnace, large mesh belt furnace, improve metallographic inspection equipment, material failure analysis, scientific management and complete, rigorous technology, skilled operation.

Company will be excellent quality and perfect service, and actively challenge, satisfy customer demand, has passed ISO9001:2000 in 2003 September (SGS) international quality certification. Has now become a reputable manufacturers.

Su's heat treatment (Shenzhen) Co., Ltd. Guangdong ICP No. 14020634

service hotline: 0755-27291255

Fax: support for 0755-27293730

E-MAIL:sushirechuli@163.com

Company address: Shenzhen, Baisha bridge Second Industrial Zone No. 14